CONTROL SYSTEMS & SERVICES

Rebus has 20 years of experience in the design and manufacture of Industrial Control Systems. Rebus can design and supply hardware and software to interface with existing plant or newly configured packages. Rebus can provide a comprehensive list of resources ranging from project management through to site services, including:

-

PLC Software design

-

Control panels and Workstations for operation in hazardous and safe areas

-

Motor Control Centres

-

A.C Drive Systems

-

Full Documentation package including detailed drawings and manuals

-

Site installation and commissioning

-

Project Management

-

Maintenance

-

Technical Advice

-

Fault Diagnostics

-

Management information systems

-

Data transfer

-

Customer Training

AUTOMATION

Rebus engineers have a wide knowledge and experience of software design with a number of PLC systems including:

-

Allen Bradley

-

Omron

-

Siemens

-

Schneider

-

Mitsubishi

-

GE Fanuc

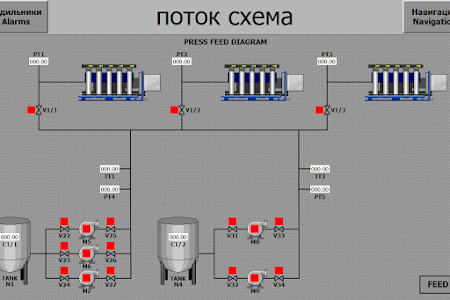

Operator Touch Screens are becoming an integral part of plant control systems. Rebus can offer a variety of Operator Touch Screens compatible with the PLC system specified.

All software development is carried out in-house, and can be tailored to client’s specific requirements.

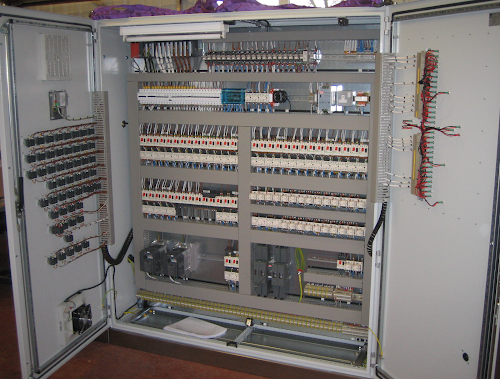

CONTROL SYSTEMS AND MOTOR CONTROL CENTRES

Control panels built to a very high standard, encompassing project requirements for size, components and technical specifications.

MCC design can be tailored to individual project electrical and mechanical parameters, incorporating ASTA rated busbar systems, Form 2, 3 and 4 specifications and front / rear / withdrawable access options.

Technical advice & recommendations given where required by our experienced engineers.

HAZARDOUS AREA SYSTEMS

Rebus specialise in the design, manufacture and testing of hazardous area control systems to ATEX or IECEx standards.

Pressurisation of enclosures is a technique for “safe area” equipment operating in hazardous areas. The pressure within the panel is raised above the external atmosphere to prevent potentially explosive gases from entering the panel during operational conditions.

Prior to a package becoming operational, a “purge cycle” is initialised to change the internal volume of the air within the control panel several times to remove any gas pockets. On satisfactory completion of the “purge cycle” electrical energy can be applied to the control system.Rebus provide systems incorporating increased safety, intrinsic safety, flameproof enclosures & non-sparking designs.

VARIABLE SPEED DRIVE SYSTEMS